One of the new pieces of the Gen4 Skandic/Expy is the primary clutch, now a pDrive in place of the eDrive and eDrive2 we all got used to, and tooled up for.

Some questions for those of you that have performed some work on these so far:

1. PDrive Puller, C&T's OK?

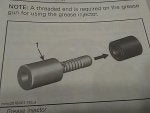

2. Roller greasing. I am reading 3-5k km's is the best interval to do this. C&T makes a tool/needle adaptor that apparently allows you to do this on the sled, I have to learn how to do this. Would like to hear your tips if you have done it already, particularly if the clutch has to be on the bench to service properly.

3. Service tools. Do I need all of the $300US kit from C&T to keep this thing going, or just the puller and the clutch holder for re-torqueing? That's all I really had for the eDrive and that got me by for years.

Some questions for those of you that have performed some work on these so far:

1. PDrive Puller, C&T's OK?

2. Roller greasing. I am reading 3-5k km's is the best interval to do this. C&T makes a tool/needle adaptor that apparently allows you to do this on the sled, I have to learn how to do this. Would like to hear your tips if you have done it already, particularly if the clutch has to be on the bench to service properly.

3. Service tools. Do I need all of the $300US kit from C&T to keep this thing going, or just the puller and the clutch holder for re-torqueing? That's all I really had for the eDrive and that got me by for years.