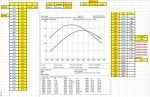

Has anyone Repowered an Old Sled with one of these cheap 4 Stroke Honda/Briggs/Clone's? Duromax makes a 440cc, 18hp@3600rpm Single. With some minor Mods can make 35-40hp. $289 with Electric Start. Most of these Engines come Stock with a Low 8.0-8.2 CR. To Rev Higher than 3800-4000rpm depending on Brand of Engine, you need to Install a Hi Rev kit or the valves will Float.

Disable the Governor, and Low Oil Sensor.

Install a Hi-Rev kit for 5500rpm.

If you intend to turn Faster than 5000rpm you need the Billet Flywheel & Billet Rod Upgrade.

These Engines come with real small Carbs 22-24mm, so you want to Upgrade to 32-34mm.

Stock Air Filters are real Restrictive, so need replaced with a K&N Type Air Filter.

The Stock Exhaust is also real Restrictive, so need replaced with a Tuned Exhaust Header Pipe.

The most useful Engines are all Based off the Honda GX390(88mm x 64mm) 389.4cc and for now go up all the way to (96mm x 86.5mm) 626.3cc. 100mm is Max Big Bore. There is multiple Bores and Strokes as different CR's availabe.

Duromax 18hp and 625 in Black from Vegas Carts

Disable the Governor, and Low Oil Sensor.

Install a Hi-Rev kit for 5500rpm.

If you intend to turn Faster than 5000rpm you need the Billet Flywheel & Billet Rod Upgrade.

These Engines come with real small Carbs 22-24mm, so you want to Upgrade to 32-34mm.

Stock Air Filters are real Restrictive, so need replaced with a K&N Type Air Filter.

The Stock Exhaust is also real Restrictive, so need replaced with a Tuned Exhaust Header Pipe.

The most useful Engines are all Based off the Honda GX390(88mm x 64mm) 389.4cc and for now go up all the way to (96mm x 86.5mm) 626.3cc. 100mm is Max Big Bore. There is multiple Bores and Strokes as different CR's availabe.

Duromax 18hp and 625 in Black from Vegas Carts