I started this thread on Home Built Airplanes, and haven't gotten a good answer yet.

How do you figure these 2 Stroke Carb CFM Rating? They are just listed as 30mm, 32mm, 34mm, etc?

Like a 293cc Twin run to 7800rpms requires a 40cfm Rating.

http://www.4secondsflat.com/Carb_CFM_Calculator.html

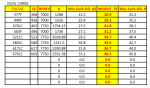

I understand the CFM Basic's for Auto Carbs, we have them CFM Numbers to work with. In these Rotax UL/Snowmobile 2 stroke Carbs we don't. We have Rotax UL engines with mainly, 34mm, or 36mm, and then we have there Snowmobile counter parts with any thing from mainly 30mm, 34mm, 36mm, 38mm, 40mm, 44mm.

That's Why, I'm asking, is there a way to figure their CFM Rating? The Higher Rpm's you Turn them the more Air they need.

Like the 293cc Skidoo Twin run at 7800rpms, the Peak Flow Calc says Peak Intake Flow Rate is, 73 cfm.

http://www.mk5cortinaestate.co.uk/calculator3.php

The Carb Calc says the 293cc run at 7800rpms needs a 40cfm Carb. All we have is Carbs in mm Size rating.

http://www.4secondsflat.com/Carb_CFM_Calculator.html

The Carb Size used does play into the HP made. Example: a 2004 550F(553cc) with 34mm Carbs Dynoed 70hp at 7000rpms. Later 550F's only come with 30mm Carbs, and are rated 58hp at 6800rpms. If ran up to 7000rpms, it probably would make 60hp, so going from 34mm to 30mm cost 10hp on the same engine.

Sleds Speed up, slow down, stop, speed up, slow down stop, etc. Ultralight's/Airplanes are used at a more continious rpms, usually 75% of Max Power for hours. Since Planes takeoff using Max Rpm's/Full Power you need to know the Size of Carb that gives you the most Power for them Spec's.

So, if for 293cc 73cfm is needed at 7800rpms, which best Carb fit's the bill? It also makes a difference if running a Single vs Dual Carbs.

How do you figure these 2 Stroke Carb CFM Rating? They are just listed as 30mm, 32mm, 34mm, etc?

Like a 293cc Twin run to 7800rpms requires a 40cfm Rating.

http://www.4secondsflat.com/Carb_CFM_Calculator.html

I understand the CFM Basic's for Auto Carbs, we have them CFM Numbers to work with. In these Rotax UL/Snowmobile 2 stroke Carbs we don't. We have Rotax UL engines with mainly, 34mm, or 36mm, and then we have there Snowmobile counter parts with any thing from mainly 30mm, 34mm, 36mm, 38mm, 40mm, 44mm.

That's Why, I'm asking, is there a way to figure their CFM Rating? The Higher Rpm's you Turn them the more Air they need.

Like the 293cc Skidoo Twin run at 7800rpms, the Peak Flow Calc says Peak Intake Flow Rate is, 73 cfm.

http://www.mk5cortinaestate.co.uk/calculator3.php

The Carb Calc says the 293cc run at 7800rpms needs a 40cfm Carb. All we have is Carbs in mm Size rating.

http://www.4secondsflat.com/Carb_CFM_Calculator.html

The Carb Size used does play into the HP made. Example: a 2004 550F(553cc) with 34mm Carbs Dynoed 70hp at 7000rpms. Later 550F's only come with 30mm Carbs, and are rated 58hp at 6800rpms. If ran up to 7000rpms, it probably would make 60hp, so going from 34mm to 30mm cost 10hp on the same engine.

Sleds Speed up, slow down, stop, speed up, slow down stop, etc. Ultralight's/Airplanes are used at a more continious rpms, usually 75% of Max Power for hours. Since Planes takeoff using Max Rpm's/Full Power you need to know the Size of Carb that gives you the most Power for them Spec's.

So, if for 293cc 73cfm is needed at 7800rpms, which best Carb fit's the bill? It also makes a difference if running a Single vs Dual Carbs.