This DIY Dyno was built for Testing Small Honda/Clone 4 Strokes. To do these Old 12hp to 50hp Sled Engines you just need a bigger Hydraulic Pump and Pressure Gauge. Homemade Dyno, small engine DIY dynamometer.

I put together a homemade small engine Dyno for a DIY build, to tune some kart and mini bike engines. Subscribe to see how I'm breaking it in with futures videos and doing calculation for HP ratings! I've been discussing many things with DIY dyno groups and people with similar machines to get the most accurate break in and test procedure as can find! I will be making minor adjustments as listed in the video, based on what I find to be best!

I'm going to be tuning engines for go karts, race kart engine tuning and mini bikes. I wanted to have a home made dyno that could do about 20 HP. I have not tested the limits yet. Due to how this video took 2 months to source all parts and with "world events" get them to me, I'm putting this up for the how to make a small engine dyno portion. Subscribe and check back to see how I use it and check horsepower gains for performance engine tuning!

I've still got my Tillotson 212r race engine video to compare to the Predator 212 non hemi engine, but the Tillotson engine is having a few performance issues. It's coming as soon as I can get it up and going. Lots of Corona projects delayed, but they are still on the way!

Total cost for this Small Engine Dyno was $500 plus tax and shipping.

I called a few other places, their dynos cost anywhere from $5000 for a base model without computer graph, to $15,000 with computer print out and all the bels and whistles. I have seen used dyno cost $4,000 for inertia dynos to $8,000 used. Some water brake and hydraulic dynamometers cost $3,000 to $8,000 used.

So basically I'm cheap, and want to tune engines.

-- Parts for instructions for my DIY Dyno seen in video --

Parts coming from Hydraulics Direct in Colorado USA:

5/8" ORB (SAE 10) Male x 1/2" NPTF Female - (Note: can use swivel female adapter here instead for ease).

3/4" ORB (SAE 12) Male x 3/4" NPTF Female - (Note: can use swivel female adapter here instead for ease).

https://www.hydraulicsdirect.com/ORB

1/2" NPTF Male x 1/2" NPTF Male (*QTY 2*).

https://www.hydraulicsdirect.com/NPTF

Extender - 1/2" NPTF Male x 1/2" NPTF Female/

https://www.hydraulicsdirect.com/NPTF

Union Tee - 1/2" NPSM Swivel x 1/2" NPSM Swivel x 1/2" NPSM Swivel.https://www.hydraulicsdirect.com/NPSM

90 degree Elbow - 1/2" NPTF Male x 1/2" NPSM Swivel.

90 degree Elbow - 1/2" NPTF Male x 1/4" NPSM Swivel.

90 degree Elbow - 3/4" NPTF Male to 1/2" NPSM Swivel.

90 degree Elbow - 3/4" NPTF Male to 3/4" NPSM Swivel (*QTY 2*).https://www.hydraulicsdirect.com/NPTF

Note: extra mentioned "ease of assembly parts" - I recommend getting as you'll see in my next video

1/2" NPTF Male x 1/2" NPSM Swivel [$2.69 each]

3/4" NPTF Male x 3/4" NPSM Swivel (*QTY 3*) [$3.24 each]

Note: I used discount code "new20" to save money. It may still work.

Part coming from BMI Karts:

Fully Adjustable Motor Mount Plate with bolt kit. $28

https://www.bmikarts.com/Motor-Mount

Parts coming from Amazon, but can come from other sources:

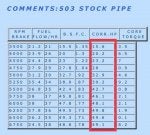

Dynamic Fluid Components hydraulic pump with 3/4" shaft and key (CLOCKWISE direction - NOTE that most CLONE engines run counter clockwise) GP-F20-20-PL-C.

$114.99 Northern Tool.

https://www.amazon.com/gp/product/B00

Hydraulic Hose 3/4" x 48" 2-wire Male to Male. $20

https://www.amazon.com/gp/product/B00

Hydraulic Hose 1/2" x 48" 2-wire Male to Male. $25

https://www.amazon.com/gp/product/B00

5 Gallon Field Tuff Hydraulic Fluid Reservoir. $72

https://www.amazon.com/gp/product/B07

2 1/2" pressure gauge, liquid filled 0-2000 PSI 1/4" mount NPT (Note: I upgraded to this 3,000 PSI since video was made). $14.70

https://www.amazon.com/gp/product/B01

In-Line Variable Control Valve 1/2" NPT connections. $34.50

https://www.amazon.com/gp/product/B07

Thread reducer bushing 1 1/2" Male to 3/4" Female NPT.

https://www.amazon.com/gp/product/B01

Teflon thread tape Digital tachometer (Note: not the best option for high RPMs AND needs to be mounted directionally for the magnet if used).

https://www.amazon.com/gp/product/B01

10' #40 chain with 2 master links. $17.25

https://www.amazon.com/gp/product/B01

3/4" centrifugal clutch 10 tooth, 420 chain sprocket. $34.99

https://www.amazon.com/gp/product/B07

#40 size 36 tooth sprocket 3/4" bore. $31.99

https://www.amazon.com/gp/product/B07

Coming from Tractor Supply: $25.25

5 gallons hydraulic fluid.

Coming from hardware store:

1 1/4" x 3/8" carriage bolts with metal locking nuts (*QTY 2*)

2 1/2" x 1/4" bolts with washers and nuts (*QTY 4*)

5/8" x 1/4" bolts with metal locking nuts (*QTY 4*)

Can save money by using Propane or other tank, if you have an older tach. If already have clutch, if already have mounting plate, if anything goes on sale.

==========================================

2-1/2" Pressure Gauge, Stainless Steel Case, Liquid Filled, Lower Mnt. 5000 PSI eBay Brand New $10.95

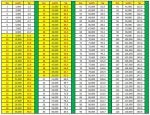

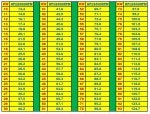

Pump has a rating on flow. Tachometer for rpm. Pressure from the gauge. Math from here: http://www.controlledmotion.com/fluidpowerformulas.html

Pump has a rating on flow. Tachometer for rpm. Pressure from the gauge. Math from here: http://www.controlledmotion.com/fluidpowerformulas.html

I put together a homemade small engine Dyno for a DIY build, to tune some kart and mini bike engines. Subscribe to see how I'm breaking it in with futures videos and doing calculation for HP ratings! I've been discussing many things with DIY dyno groups and people with similar machines to get the most accurate break in and test procedure as can find! I will be making minor adjustments as listed in the video, based on what I find to be best!

I'm going to be tuning engines for go karts, race kart engine tuning and mini bikes. I wanted to have a home made dyno that could do about 20 HP. I have not tested the limits yet. Due to how this video took 2 months to source all parts and with "world events" get them to me, I'm putting this up for the how to make a small engine dyno portion. Subscribe and check back to see how I use it and check horsepower gains for performance engine tuning!

I've still got my Tillotson 212r race engine video to compare to the Predator 212 non hemi engine, but the Tillotson engine is having a few performance issues. It's coming as soon as I can get it up and going. Lots of Corona projects delayed, but they are still on the way!

Total cost for this Small Engine Dyno was $500 plus tax and shipping.

I called a few other places, their dynos cost anywhere from $5000 for a base model without computer graph, to $15,000 with computer print out and all the bels and whistles. I have seen used dyno cost $4,000 for inertia dynos to $8,000 used. Some water brake and hydraulic dynamometers cost $3,000 to $8,000 used.

So basically I'm cheap, and want to tune engines.

-- Parts for instructions for my DIY Dyno seen in video --

Parts coming from Hydraulics Direct in Colorado USA:

5/8" ORB (SAE 10) Male x 1/2" NPTF Female - (Note: can use swivel female adapter here instead for ease).

3/4" ORB (SAE 12) Male x 3/4" NPTF Female - (Note: can use swivel female adapter here instead for ease).

https://www.hydraulicsdirect.com/ORB

1/2" NPTF Male x 1/2" NPTF Male (*QTY 2*).

https://www.hydraulicsdirect.com/NPTF

Extender - 1/2" NPTF Male x 1/2" NPTF Female/

https://www.hydraulicsdirect.com/NPTF

Union Tee - 1/2" NPSM Swivel x 1/2" NPSM Swivel x 1/2" NPSM Swivel.https://www.hydraulicsdirect.com/NPSM

90 degree Elbow - 1/2" NPTF Male x 1/2" NPSM Swivel.

90 degree Elbow - 1/2" NPTF Male x 1/4" NPSM Swivel.

90 degree Elbow - 3/4" NPTF Male to 1/2" NPSM Swivel.

90 degree Elbow - 3/4" NPTF Male to 3/4" NPSM Swivel (*QTY 2*).https://www.hydraulicsdirect.com/NPTF

Note: extra mentioned "ease of assembly parts" - I recommend getting as you'll see in my next video

1/2" NPTF Male x 1/2" NPSM Swivel [$2.69 each]

3/4" NPTF Male x 3/4" NPSM Swivel (*QTY 3*) [$3.24 each]

Note: I used discount code "new20" to save money. It may still work.

Part coming from BMI Karts:

Fully Adjustable Motor Mount Plate with bolt kit. $28

https://www.bmikarts.com/Motor-Mount

Parts coming from Amazon, but can come from other sources:

Dynamic Fluid Components hydraulic pump with 3/4" shaft and key (CLOCKWISE direction - NOTE that most CLONE engines run counter clockwise) GP-F20-20-PL-C.

$114.99 Northern Tool.

https://www.amazon.com/gp/product/B00

Hydraulic Hose 3/4" x 48" 2-wire Male to Male. $20

https://www.amazon.com/gp/product/B00

Hydraulic Hose 1/2" x 48" 2-wire Male to Male. $25

https://www.amazon.com/gp/product/B00

5 Gallon Field Tuff Hydraulic Fluid Reservoir. $72

https://www.amazon.com/gp/product/B07

2 1/2" pressure gauge, liquid filled 0-2000 PSI 1/4" mount NPT (Note: I upgraded to this 3,000 PSI since video was made). $14.70

https://www.amazon.com/gp/product/B01

In-Line Variable Control Valve 1/2" NPT connections. $34.50

https://www.amazon.com/gp/product/B07

Thread reducer bushing 1 1/2" Male to 3/4" Female NPT.

https://www.amazon.com/gp/product/B01

Teflon thread tape Digital tachometer (Note: not the best option for high RPMs AND needs to be mounted directionally for the magnet if used).

https://www.amazon.com/gp/product/B01

10' #40 chain with 2 master links. $17.25

https://www.amazon.com/gp/product/B01

3/4" centrifugal clutch 10 tooth, 420 chain sprocket. $34.99

https://www.amazon.com/gp/product/B07

#40 size 36 tooth sprocket 3/4" bore. $31.99

https://www.amazon.com/gp/product/B07

Coming from Tractor Supply: $25.25

5 gallons hydraulic fluid.

Coming from hardware store:

1 1/4" x 3/8" carriage bolts with metal locking nuts (*QTY 2*)

2 1/2" x 1/4" bolts with washers and nuts (*QTY 4*)

5/8" x 1/4" bolts with metal locking nuts (*QTY 4*)

Can save money by using Propane or other tank, if you have an older tach. If already have clutch, if already have mounting plate, if anything goes on sale.

==========================================

2-1/2" Pressure Gauge, Stainless Steel Case, Liquid Filled, Lower Mnt. 5000 PSI eBay Brand New $10.95

Pump has a rating on flow. Tachometer for rpm. Pressure from the gauge. Math from here: http://www.controlledmotion.com/fluidpowerformulas.html

Pump has a rating on flow. Tachometer for rpm. Pressure from the gauge. Math from here: http://www.controlledmotion.com/fluidpowerformulas.html