I have about 3300 miles on my 2020 BC- xrs and was wondering when most of you change your Secondary rollers? I had the primary rollers fail on me last year and was wondering if most change them early or wait for failure? Also, are you all using stock rollers? I saw in a magazine that G- Boost belts is advertising new rollers. Anyone use them?

850 secondary rollers - when to change andnwhich brand?

ray628

Discussion starter

1,158 posts

·

Joined 2003

- Add to quote Only show this user

I have about 3300 miles on my 2020 BC- xrs and was wondering when most of you change your Secondary rollers? I had the primary rollers fail on me last year and was wondering if most change them early or wait for failure? Also, are you all using stock rollers? I saw in a magazine that G- Boost belts is advertising new rollers. Anyone use them?

181 posts

·

Joined 2017

Roller on secondary broke at 6,000 miles on my 850. Going to start changing at 5,000 miles from now on. Just replaced with ski Doo rollers

916 posts

·

Joined 2003

I change to the Fett Brothers Hi- torque rollers right away. the stock ones will leave you stranded eventually.

866 posts

·

Joined 2019

same as evil dooer. before my sled hits the snow i put in an ibackshift clutch kit and hi torque secondary rollers.

4,106 posts

·

Joined 2004

I had a set fail at just under 900 miles on a 600 ETEC, no less. It's a crap shoot.

Now, all of my stock secondary rollers get replaced with aftermarket "hi-torque" rollers at the first service visit. They are relative cheap and it's not worth the risk to postpone replacement.

Now, all of my stock secondary rollers get replaced with aftermarket "hi-torque" rollers at the first service visit. They are relative cheap and it's not worth the risk to postpone replacement.

263 posts

·

Joined 2018

We have been testing all kinds of rollers on the market, and GBoost Extreme Rhino rollers have been the best so far. Not a single one has broken so far and we have been installing these since 2020 spring. We used to install hitorque rollers, but since quality issues we had to find alternative.

www.gboosttechnology.com

www.gboosttechnology.com

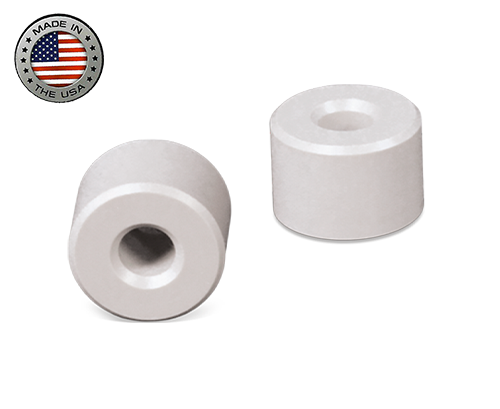

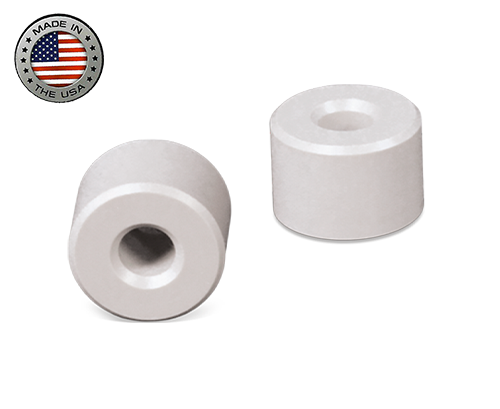

RR4EXB - EXTREME RHINO ROLLER™ KIT - Can-Am/Ski-Doo - 2 Rollers per pkg

EXTREME RHINO ROLLER Kit 2 Pack Driven Clutch Upgrade Fitment: All Can-AM Models w/2 Roller Driven Clutch 2018-2022 Maverick Trail / Sport 1000 & 800 Note: Sport 1000R models Use RR3B3 or RR3EXB 2015-2017 Maverick 1000 Turbo XDS-DPS / Max 2016-2019 Defender HD10 / MAX 2016-2021 Defender...

167 posts

·

Joined 2016

Roller longevity depends a good bit on how you ride and how easy you are on the reverse to forward/vice versa transition, that smacking noise heard most times is the rollers hitting the opposing helix face. I replace mine seasonally (average around 3k miles a season) just to be extra safe and not ruin a ride. The Gboost Rhino Rollers are awesome pieces, the Extreme version's even better.

4,106 posts

·

Joined 2004

Correct!Roller longevity depends a good bit on how you ride and how easy you are on the reverse to forward/vice versa transition, that smacking noise heard most times is the rollers hitting the opposing helix face.

Always come to a COMPLETE stop before engaging reverse and ease into the throttle when using reverse.

263 posts

·

Joined 2018

Yes, especially when secondary/rollers are still cold and you hit reverse uncarefully, is the situation where the damage is mostly done.

Once I saw a post on FB where this company was testing QRS rollers on both warm and cold conditions. Some of the rollers were doing fine when warm but were extremely weak when cold.

Once I saw a post on FB where this company was testing QRS rollers on both warm and cold conditions. Some of the rollers were doing fine when warm but were extremely weak when cold.

285 posts

·

Joined 2007

Where I work, we use Thunder Products rollers, haven’t had any fail on customers since replacing.

866 posts

·

Joined 2019

you need a long punch to remove the pins. i also use a shorter punch to initially get the pin pushed out a bit because the long one flexes so much.

also whatever tools required to remove the secondary plus not drop the top chaincase gear down into the case when pulling the secondary and jackshaft out.

secondary clutch tools to allow you to relieve spring tension and diassemble it to get to the rollers.

torch to loosen loctite on the 4 secondary torx bolts.

also whatever tools required to remove the secondary plus not drop the top chaincase gear down into the case when pulling the secondary and jackshaft out.

secondary clutch tools to allow you to relieve spring tension and diassemble it to get to the rollers.

torch to loosen loctite on the 4 secondary torx bolts.

9,590 posts

·

Joined 2004

You must have never had to do a 12 point turn around to get out of the trees in deep snow. hahaha

9,590 posts

·

Joined 2004

GW's seem to have nice lookin ones although ive never tested em' myself.

Super good roller change vidya

664 posts

·

Joined 2018

Hi-torque are definitely the way to go, we have them installed on all 3 of our renegades

459 posts

·

Joined 2018

Good vid, but I suspect there are some tricks/tools needed to take apart the clutch as he had the sheeves apart and the helix sitting on the bench.

11,664 posts

·

Joined 2006

We have been selling and installing the Hi-Torque Rollers for years. Excellent quality.

6,259 posts

·

Joined 2007

Unfortunately, rollers are a bit like belt life. Some get much longer life than others depending on riding style. However, I would say that you should at least get 5000 miles and 10000 would be on borrowed time.

The rollers are very cheap and when one breaks it ruins a good ride. So with that in mind, it’s worthwhile to switch to Hi-torque or similar - just not OEM’s.

As for tools, yes you’ll need a few but Chris sells them and they are worthwhile to have. Not crazy expensive and they should be good for many years. When I purchase tools I always feel they are a wise purchase as if I had to get someone to do the work it would cost substantially more.

The rollers are very cheap and when one breaks it ruins a good ride. So with that in mind, it’s worthwhile to switch to Hi-torque or similar - just not OEM’s.

As for tools, yes you’ll need a few but Chris sells them and they are worthwhile to have. Not crazy expensive and they should be good for many years. When I purchase tools I always feel they are a wise purchase as if I had to get someone to do the work it would cost substantially more.

866 posts

·

Joined 2019

anytime the helix slams into the rollers, there's the potential to shatter them and that's a frequent occurrence when riding. buddy's sled went down due to this at only 400 or so miles on it and ended the day. doesn't take cumulative wear or age for the rollers to crack.

263 posts

·

Joined 2018

We haven´t installed Hitorque rollers for couple of years now. Too many problems, quality isnt where it used to be. These ones lasted for 700km on a summit expert.

![]()

What comes to GBoost Extreme Rhino rollers, not a single set has come back yet.

2023 850TurboR is gonna have new stronger rollers, interesting to see how those are like

1h 12min:

What comes to GBoost Extreme Rhino rollers, not a single set has come back yet.

2023 850TurboR is gonna have new stronger rollers, interesting to see how those are like

1h 12min:

11,664 posts

·

Joined 2006

You must have received a bad set or something. We have sold hundreds and hundreds of sets for the last ten years and never had an issue or complaint. If these were not a quality and dependable replacement part we would not be selling them.

Not trying to knock the G boost at all but they haven't been on the market very long.

Not trying to knock the G boost at all but they haven't been on the market very long.

263 posts

·

Joined 2018

Yeah we used to install a lot hitorque rollers and for a long time and it was my recommendation too. Problems begun back in 2019 and for two seasons I would say at least 50% were broken way too early, especially with sleds that had clutchkit with aggressive setup and higher angle helix. Also the large distributor here saw the issue as lots of complaints flooded. And I believe lot of people dont bother to even complain, they just buy new ones from another brand or change back to stock ones. My first thought was also that it must be a bad patch of products, but afterall all shipments 2019-2020 were the same. We even contacted the manufacturer straight but they claimed nothing had changed, even though you could see the color difference between 2018 and 2019 rollers. I really hope they have got their product back to quality it was but in my opinion there are better options nowdays.

866 posts

·

Joined 2019

@Driver#96,

thanks for posting that vid which i'd seen before but missed the part about new factory rollers.

in the pic you showed, is that what hi torque rollers look like after they've been used? the larger pieces look metallic as opposed to what looks almost like phenolic material when they are new.

thanks for posting that vid which i'd seen before but missed the part about new factory rollers.

in the pic you showed, is that what hi torque rollers look like after they've been used? the larger pieces look metallic as opposed to what looks almost like phenolic material when they are new.

263 posts

·

Joined 2018

Lets hope these new rollers are strong and in the future no need to replace them with aftermarket ones. Im a bit surprised that doo didnt promote them at all.@Driver#96,

thanks for posting that vid which i'd seen before but missed the part about new factory rollers.

in the pic you showed, is that what hi torque rollers look like after they've been used? the larger pieces look metallic as opposed to what looks almost like phenolic material when they are new.

Yes those rollers in the picture are from my ex 2020 expert and lasted around 700km. Hitorque rollers are some kind of fibre material an they tend to "compress" in use as you can see. All hitorque rollers looke like that after some riding.

11,664 posts

·

Joined 2006

At least 50%?? Haha! What a crock! LMAO! Complete BS.

I'd be willing to bet that at least 25% of the members here on this forum run Hi Torque. If there were many failures you would see it right here in this thread.

Feel free to promote your favorite roller to help increase your sales but no need to bash the others.

I'd be willing to bet that at least 25% of the members here on this forum run Hi Torque. If there were many failures you would see it right here in this thread.

Feel free to promote your favorite roller to help increase your sales but no need to bash the others.

263 posts

·

Joined 2018

Personally I dont sell anything, but do a lot clutching, testing, r&d. Promoting here does not even do anything in our market, as in Dootalk 99% of users are north americans.

One thing to consider that here in Europe we ride quite low elevations. That means we are able to use steeper angle helixes and harder secondary springs even on deep snow conditions. That equals more pressure and stress for the rollers. I have visited BC twice, and can say that conditions, clutching and problems with machines are quite different than we have here.

I bet rollers are more of an issue here than other side of the sea. And the same goes with belts, 2018 was catastrophical. But companies only look numbers, something that is major issue here can seem as minor inconvience on corporate numbers. After all its a numbers game.

One thing to consider that here in Europe we ride quite low elevations. That means we are able to use steeper angle helixes and harder secondary springs even on deep snow conditions. That equals more pressure and stress for the rollers. I have visited BC twice, and can say that conditions, clutching and problems with machines are quite different than we have here.

I bet rollers are more of an issue here than other side of the sea. And the same goes with belts, 2018 was catastrophical. But companies only look numbers, something that is major issue here can seem as minor inconvience on corporate numbers. After all its a numbers game.

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 8M

- members

- 175K

- Since

- 2002

A forum community dedicated to Ski-doo snowmobile owners and enthusiasts. Come join the discussion about trails, racing, performance, modifications, classifieds, troubleshooting, maintenance, and more!

Our Vendors

View AllTop Contributors this Month

View All

bossboy

953 Replies

ronsmith409

686 Replies

UnoMas?

460 Replies