Craigslist Ad says, it's suppose to be a 1971 - 72 Ski-Doo Rotax 335 Cylinder, or is it a 340 TNT Cylinder? It looks to have better Porting than some 335 Cylinders I have seen.

1971 - 72 Ski-Doo Rotax 335 or 340 TNT Cylinder?

41 - 60 of 66 Posts

Joined

·

3,595 Posts

335/340 TNT Intake Port with Overbore's to .080". I bought a 335 .040" off eBay the other day, but there is some larger up to .080" or 2mm. Wiseco has some to 1.5mm and 2.0mm.

Attachments

-

82.8 KB Views: 97

Good luck with that.....I bought a 335 .080" off eBay the other day.

Joined

·

3,595 Posts

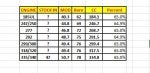

Using the Intake Port 65% Max Rule what you could go on these Old Singles. If we can collect the Stock Intake Port Spec's to compare.

Attachments

-

29.8 KB Views: 99

Joined

·

3,595 Posts

Yep, my bad, the one I bought is: NEW NOS SNOWMAX PISTON KIT 09-746-04 SKI-DOO 335 Olympique 1969-1973 .040 OVER.Good luck with that.....

OEM Replacement Ski-Doo 420-9850-55

CC 334.5

Bore (mm) 78+0.040

Stroke (mm) 70

Number of Cylinders 1

Size 40 OVER

Fits 69-72 SkiDoo Olympic 335; 70-73 Ski-Doo Skandic

I was told you could Bore most Stock Cylinders up to .080" or 2mm if you can find a Piston. I have seen some that big over the years. Minimum Piston Wall needed is 2mm per Dave from LA Sleeve. Measure the OD of your Engines Sleeve and minus 4mm, that is the Max Bore it can go to. Different Sleeve Wall Thickness does vary!

Hepolite piston rotax 17935 2.9921" + .080" 76mm + 2.032mm 12 69 CG 300 302 320

WISECO Piston only +.080 over Bore 68mm, 2140P8, Ski Doo Rotax 250 (247 Single)

New Wiseco Ski Doo Piston Kit # 2144P8 .080 OS 64mm Rotax 371cc

Wiseco 2144 P8 Full Piston Kit with Rings Ski Doo Rotax 369 Twin .080 LEFT ONLY

Joined

·

1,323 Posts

So...... Max Carb selectionWhat do you figure a 340 TNT Cylinder can handle for Max Carb Size? With the 335/340 TNT Intake Ports both 47mm Wide, could they be made a little Wider? Any Pro's/Con's on doing that?

If you have ever heard the the phrase "time-area" of ports - you know that most books get very detailed about how to figure it etc. Short version of the story - for PISTON PORT intakes.

When the engine is running the the piston bottom edge starts with just a little slit of the port open. On its way up its always uncovering more and more of the port. At TDC the port is fully open.

On the way down - the opposite thing happens. Port starts wide open gets smaller and smaller till closed completely. The only part of the port that is open the entire time? - that very first little slit.

SO...... what you have is a full sized port for only a few milliseconds - and some smaller port the rest of the time. That is the whole time-area discussion - trying to determine the average size of the port during the time it is open.

Why is it important? - because if you "over-carb" low end response suffers and engines get hard to start. Even today if you walk the pits at vintage sled races, you will see sleds being started with Squirt bottles of fuel. Loved the Citation 3500's with primers ...

Luckily for rectangular ports the math is kinda simple and some typical numbers have been generated over the years for carb selection. The following effective port size guidelines are common. Your milage may vary .....

RACING - 100% of physical port area - racers want most possible even if port is fully open only a short time. Best top end power - poor low end

HOT TRAIL riding - 75% physical port area - good top end power and reasonable mid range

REGULAR trail - 65% physical port area - good low end and mid range power

For the 335 it amounts to

Total window area ..... 335 - 26.5x47 = 1246 sq mm

1246 x 65% = 809 = 32mm circle - Stock 335 carb.

1246 x 75% = 935 = 34.5mm circle

1246 x 100% = 1246 = 39+mm circle

TNT 340

Total window area ..... 29x47 = 1363 sq mm

1363 x 65% = 886 = 33.6 mm

1363 x 75% = 1022 = 36 mm - Tillys come in two sizes 32 and 38. So 38 used.

1363 x 100% = 41+ mm circle -

Back in the day racers bored to Tillys larger than 38. I have one bored to 40. Heard of bigger.

Now just practical experience from one lungers at the race track - On short tracks guys running 38s have better hole shots - and come out of the corners better. 44's have better top end at the end of the straight on long tracks

Attachments

-

165.9 KB Views: 94

Joined

·

3,595 Posts

https://ncalculators.com/area-volume/circle-calculator.htmSo...... Max Carb selection

If you have ever heard the the phrase "time-area" of ports - you know that most books get very detailed about how to figure it etc. Short version of the story - for PISTON PORT intakes.

When the engine is running the the piston bottom edge starts with just a little slit of the port open. On its way up its always uncovering more and more of the port. At TDC the port is fully open.

On the way down - the opposite thing happens. Port starts wide open gets smaller and smaller till closed completely. The only part of the port that is open the entire time? - that very first little slit.

SO...... what you have is a full sized port for only a few milliseconds - and some smaller port the rest of the time. That is the whole time-area discussion - trying to determine the average size of the port during the time it is open.

Why is it important? - because if you "over-carb" low end response suffers and engines get hard to start. Even today if you walk the pits at vintage sled races, you will see sleds being started with Squirt bottles of fuel. Loved the Citation 3500's with primers ...

Luckily for rectangular ports the math is kinda simple and some typical numbers have been generated over the years for carb selection. The following effective port size guidelines are common. Your milage may vary .....

RACING - 100% of physical port area - racers want most possible even if port is fully open only a short time. Best top end power - poor low end

HOT TRAIL riding - 75% physical port area - good top end power and reasonable mid range

REGULAR trail - 65% physical port area - good low end and mid range power

For the 335 it amounts to: So for the Stock 5500rpms. Maybe just Bore Intake for a 36mm Carb is probably best for 75% Hot Trail Sled.

Total window area ..... 335 - 26.5x47 = 1246 sq mm

1246 x 65% = 809 = 32mm circle - Stock 335 carb.

1246 x 75% = 935 = 34.5mm circle

1246 x 100% = 1246 = 39+mm circle

If 335 Intake Port widened to 65% 26.5mm x 50.7mm = 1343.55sq mm for maybe higher 6500+rpms. Using Chart below, it's best to round up.

1343.55 x 65% = 873.3 = 34mm

1343.55 x 75% = 1007.7 = 36mm

1343.55 x 100% = 1343.6 = 38mm Max Size a Standard 335 Cylinder can handle!

TNT 340 For the Stock 6500rpms.

Total window area ..... 29x47 = 1363 sq mm

1363 x 65% = 886 = 33.6 mm

1363 x 75% = 1022 = 36 mm - Tillys come in two sizes 32 and 38. So 38 used.

1363 x 100% = 41+ mm circle -

If TNT Intake Port widened to 65% 29mm x 50.7mm = 1470.3sq mm for higher 6500+rpms. Using Chart below, it's best to round up.

1470.3 x 65% = 955.7 = 35mm

1470.3 x 75% = 1102.7 = 38mm

1470.3 x 100% = 1470.3 = 44mm

Back in the day racers bored to Tillys larger than 38. I have one bored to 40. Heard of bigger.

Now just practical experience from one lungers at the race track - On short tracks guys running 38s have better hole shots - and come out of the corners better. 44's have better top end at the end of the straight on long tracks

Carbs in Red most common Sizes used on Rotax's!

28mm = 616.0sq mm

29mm = 660.8sq mm

30mm = 707.1sq mm

31mm = 755.1sq mm

32mm = 804.6sq mm

33mm = 855.6sq mm

34mm = 908.3sq mm

35mm = 962.5sq mm

36mm = 1018.3sq mm

37mm = 1075.6sq mm

38mm = 1134.6sq mm

39mm = 1195.1sq mm

40mm = 1257.1sq mm

41mm = 1320.8sq mm

42mm = 1386.0sq mm

43mm = 1452.8sq mm

44mm = 1521.1sq mm

45mm = 1591.1sq mm

46mm = 1662.6sq mm

47mm = 1735.6sq mm

48mm = 1810.3sq mm

49mm = 1886.5sq mm

50mm = 1964.3sq mm

Joined

·

3,595 Posts

I was rereading from the beginning of this thread. How did you figure these 335 Oly - 340 TNT at 135/145 Port Durations? Isn't that based on the Exhaust Port Spec's, Rod Length, Port Height from BDC?

I haven't measured my 335 Cylinder yet but 135 duration would mean a 17.1673mm Ex Port Height, a 145 duration would mean a 19.7391mm Ex Port Height.

Port Timing Duration

http://www.csgnetwork.com/timingportdurationcalc.html

The 335 Oly has about a 135 intake duration - 135/360 = 0.375

The 340 TNT has about a 145 intake duration - 145/360 = 0.403

Ports are measured in Degrees - so lets look at it that way

Intake Duration

120 degrees = 120/360 = 0.333

130 degrees = 130/360 = 0.361

140 degrees = 140/360 = 0.389

150 degrees = 150/360 = 0.417

160 degrees = 160/360 = 0.444

170 degrees = 170/360 = 0.472 - Practical limit for a piston port trail sled.

180 degrees = 180/360 = 0.500 - Same as 30 second example

190 degrees = 190/360 = 0.528

200 degrees = 200/360 = 0.556

210 degrees = 210/360 = 0.583

220 degrees = 220/360 = 0.611

No Snow in Iowa yet 12-17-17! 20F-40F though. Got the Glass Bead Cabinet finally fixed last night, still have to finish cleaning Cylinder up. Got a 335 short block cheap coming to apply these mods to. My Complete engines are in storage pickled.

I haven't measured my 335 Cylinder yet but 135 duration would mean a 17.1673mm Ex Port Height, a 145 duration would mean a 19.7391mm Ex Port Height.

Port Timing Duration

http://www.csgnetwork.com/timingportdurationcalc.html

The 335 Oly has about a 135 intake duration - 135/360 = 0.375

The 340 TNT has about a 145 intake duration - 145/360 = 0.403

Ports are measured in Degrees - so lets look at it that way

Intake Duration

120 degrees = 120/360 = 0.333

130 degrees = 130/360 = 0.361

140 degrees = 140/360 = 0.389

150 degrees = 150/360 = 0.417

160 degrees = 160/360 = 0.444

170 degrees = 170/360 = 0.472 - Practical limit for a piston port trail sled.

180 degrees = 180/360 = 0.500 - Same as 30 second example

190 degrees = 190/360 = 0.528

200 degrees = 200/360 = 0.556

210 degrees = 210/360 = 0.583

220 degrees = 220/360 = 0.611

No Snow in Iowa yet 12-17-17! 20F-40F though. Got the Glass Bead Cabinet finally fixed last night, still have to finish cleaning Cylinder up. Got a 335 short block cheap coming to apply these mods to. My Complete engines are in storage pickled.

Joined

·

1,323 Posts

There are three basic durations in an engineI was rereading from the beginning of this thread. How did you figure these 335 Oly - 340 TNT at 135/145 Port Durations? Isn't that based on the Exhaust Port Spec's, Rod Length, Port Height from BDC?

I haven't measured my 335 Cylinder yet but 135 duration would mean a 17.1673mm Ex Port Height, a 145 duration would mean a 19.7391mm Ex Port Height.

Port Timing Duration

http://www.csgnetwork.com/timingportdurationcalc.html

Exhaust Port Duration - degrees bettween exhaust port opening and closing

Intake Port Duration degrees bettween intake port opening and closing

Transfer Port Duration - degrees bettween transfer ports opening and closing

You can change any one of them independently of the other. (To a point)

Way back in Post #5 you you started quoting CFM and carb numbers. I have been talking about INTAKE duration ever since because that is what you need to know to properly size a carb.

We have not started any discussion on exhaust yet. 135/145 are intake numbers not exhaust.

The calculator you showed is for EXHAUST duration. The measurements would get you to the top of the exhaust port measured from BDC - Doesn't work for intakes.

PLUS - I don't like the BDC view of the ports - Virtually impossible to get close without an assembled engine. No reference point is available for BDC unless the engine is assembled.

When SPITBALLING an engine - I prefer TDC calculations. That way you can measure from the top of the cylinder - at least top of cylinder is close to TDC. All you need is a piston and cylinder to get approximate numbers.

For EXHAUST duration - measure from top of cylinder to top of exhaust port. Convert to degrees Then 360 - (2 x degrees) = Exhaust duration

http://www.torqsoft.net/piston-position.html

For INTAKE duration - slide piston into cylinder until skirt reaches bottom of intake port (just closed). Measure top of cylinder to top edge of piston. Convert to degrees Degrees x 2 = intake duration.

So yes you can figure durations by measuring, knowing rod lengths etc.

BUT - just like determining the CCs of a head - you need to MEASURE the degrees of an engine to be sure what you really have. Base gasket thickness , piston design etc can change intake /exhaust durations.

I know you can create a degree wheel with your CAD program. For years I used a simple degree wheel printout pasted to an old CD - the hole in the middle makes for a convenient place to put a bolt to fasten to the crank.

http://www.modelflying.co.uk/news/article/the-engine-lab-two-stroke-degree-wheel/2349/

Do yourself a favor before you start cutting your cylinder. When you get your short block start taking real measurements for the cylinder you want to modify.

.

Joined

·

3,595 Posts

Using Paper Rubs and a Clear Plastic Ruler I came up with these measurements.

My 335 Cylinder #813-010

Intake ID Outside: 35mm

Exhaust ID outside: 40mm

Top of Cylinder to Top of Centerline of Exhaust Port: 45mm

Exhaust Port ID: 26mm x 50mm

Intake Port ID: 27 x 50

Piston Skirt: 75mm

Piston Dome Height: 4mm

Gasket Intake Port Hole ID: 34mm ID

Gasket Intake Bolt Spacing: 8mm 50mm - 75mm

Gasket Exhaust Port Hole ID: 40mm

Gasket Exhaust Bolt Spacing: 8mm Bolts, 58mm - 75mm

Dome Height 4mm x 78mm Bore = 9.6cc

Now this Port Timing Calc doesn't say if at BDC to Top of Exhaust Port is from Edge of Piston or from Top of Piston Dome. I'm guessing Edge of Piston. I haven't confirm the Rod Length yet.

http://www.csgnetwork.com/timingportdurationcalc.html

Measured Stroke: 70mm

Connecting Rod Length: 110mm

Port Height Above BDC: 26mm

Ex Duration: 169.059

================================

Measured Stroke: 70mm

Connecting Rod Length: 115mm

Port Height Above BDC: 26mm

Ex Duration: 168.180

================================

Measured Stroke: 70mm

Connecting Rod Length: 120mm

Port Height Above BDC: 26mm

Ex Duration: 167.380

================================

Measured Stroke: 70mm

Connecting Rod Length: 125mm

Port Height Above BDC: 26mm

Ex Duration: 166.648

===============================

Measured Stroke: 70mm

Connecting Rod Length: 132mm

Port Height Above BDC: 26mm

Ex Duration: 165.722

My 335 Cylinder #813-010

Intake ID Outside: 35mm

Exhaust ID outside: 40mm

Top of Cylinder to Top of Centerline of Exhaust Port: 45mm

Exhaust Port ID: 26mm x 50mm

Intake Port ID: 27 x 50

Piston Skirt: 75mm

Piston Dome Height: 4mm

Gasket Intake Port Hole ID: 34mm ID

Gasket Intake Bolt Spacing: 8mm 50mm - 75mm

Gasket Exhaust Port Hole ID: 40mm

Gasket Exhaust Bolt Spacing: 8mm Bolts, 58mm - 75mm

Dome Height 4mm x 78mm Bore = 9.6cc

Now this Port Timing Calc doesn't say if at BDC to Top of Exhaust Port is from Edge of Piston or from Top of Piston Dome. I'm guessing Edge of Piston. I haven't confirm the Rod Length yet.

http://www.csgnetwork.com/timingportdurationcalc.html

Measured Stroke: 70mm

Connecting Rod Length: 110mm

Port Height Above BDC: 26mm

Ex Duration: 169.059

================================

Measured Stroke: 70mm

Connecting Rod Length: 115mm

Port Height Above BDC: 26mm

Ex Duration: 168.180

================================

Measured Stroke: 70mm

Connecting Rod Length: 120mm

Port Height Above BDC: 26mm

Ex Duration: 167.380

================================

Measured Stroke: 70mm

Connecting Rod Length: 125mm

Port Height Above BDC: 26mm

Ex Duration: 166.648

===============================

Measured Stroke: 70mm

Connecting Rod Length: 132mm

Port Height Above BDC: 26mm

Ex Duration: 165.722

Joined

·

3,595 Posts

Ok, Intake Duration, just wanted to be sure. I did a paper rub and came up with 27 x 50 for this Cylinders Intake Port. I didn't get any Photo's yet. I got the Piston with the Cylinder so I had something to look at. Earlier you Posted a Photo of the Piston notched on the bottom. I noticed when this Piston is at TDC the Intake Port was still partily covered by the Skirt maybe a 1/4", wouldn't you want to open that area up to be closer to the Top of the Intake Port to un-restrict it? I had traced it's Outline onto the Piston Skirt to measure later, but it rubbed off from some of the Oil I had sprayed on the cylinder. I have seen some 2 Strokes where they trim the bottom of the Piston Skirt. For the most part it looked pretty good just some minor cleanup to match stuff up.There are three basic durations in an engine

Exhaust Port Duration - degrees bettween exhaust port opening and closing

Intake Port Duration degrees bettween intake port opening and closing

Transfer Port Duration - degrees bettween transfer ports opening and closing

You can change any one of them independently of the other. (To a point)

Way back in Post #5 you you started quoting CFM and carb numbers. I have been talking about INTAKE duration ever since because that is what you need to know to properly size a carb.

We have not started any discussion on exhaust yet. 135/145 are intake numbers not exhaust.

The calculator you showed is for EXHAUST duration. The measurements would get you to the top of the exhaust port measured from BDC - Doesn't work for intakes.

PLUS - I don't like the BDC view of the ports - Virtually impossible to get close without an assembled engine. No reference point is available for BDC unless the engine is assembled.

When SPITBALLING an engine - I prefer TDC calculations. That way you can measure from the top of the cylinder - at least top of cylinder is close to TDC. All you need is a piston and cylinder to get approximate numbers.

For EXHAUST duration - measure from top of cylinder to top of exhaust port. Convert to degrees Then 360 - (2 x degrees) = Exhaust duration

http://www.torqsoft.net/piston-position.html

For INTAKE duration - slide piston into cylinder until skirt reaches bottom of intake port (just closed). Measure top of cylinder to top edge of piston. Convert to degrees Degrees x 2 = intake duration.

So yes you can figure durations by measuring, knowing rod lengths etc.

BUT - just like determining the CCs of a head - you need to MEASURE the degrees of an engine to be sure what you really have. Base gasket thickness , piston design etc can change intake /exhaust durations.

I know you can create a degree wheel with your CAD program. For years I used a simple degree wheel printout pasted to an old CD - the hole in the middle makes for a convenient place to put a bolt to fasten to the crank.

http://www.modelflying.co.uk/news/article/the-engine-lab-two-stroke-degree-wheel/2349/

Do yourself a favor before you start cutting your cylinder. When you get your short block start taking real measurements for the cylinder you want to modify.

.

Joined

·

1,323 Posts

Port rubs work ok for duration (height of port)Using Paper Rubs and a Clear Plastic Ruler I came up with these measurements.

My 335 Cylinder #813-010

Intake ID Outside: 35mm

Exhaust ID outside: 40mm

Top of Cylinder to Top of Centerline of Exhaust Port: 45mm

Exhaust Port ID: 26mm x 50mm

Intake Port ID: 27 x 50

Piston Skirt: 75mm

Piston Dome Height: 4mm

Dome Height 4mm x 78mm Bore = 9.6cc

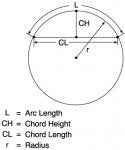

But they don't work for width of port the way you are describing. When you lay the paper flat and measure you get the Arc length- not the Chordal length See below for difference.

Early on - I used a toothpick for measuring width. Keep making it smaller with a nail clipper, until it just fits into the port. Then measure it with a ruler, micrometer, whatever you have.

Now I use an old inside caliper I found at a rummage sale.

Attachments

-

52.1 KB Views: 90

-

68.8 KB Views: 45

-

62.2 KB Views: 45

Joined

·

1,323 Posts

Do you want to trim the piston ? Yes and MaybeOk, Intake Duration, just wanted to be sure. I did a paper rub and came up with 27 x 50 for this Cylinders Intake Port. I didn't get any Photo's yet. I got the Piston with the Cylinder so I had something to look at. Earlier you Posted a Photo of the Piston notched on the bottom. I noticed when this Piston is at TDC the Intake Port was still partily covered by the Skirt maybe a 1/4", wouldn't you want to open that area up to be closer to the Top of the Port to un-restrict it? I had traced it's Outline onto the Piston Skirt to measure later, but it rubbed off from some of the Oil I had sprayed on the cylinder. I have seen some 2 Strokes where they trim the bottom of the Piston Skirt. For the most part it looked pretty good just some minor cleanup to match stuff up.

Yes - if the piston hangs down in the cylinder it is restricting flow so trimming would help that.

Maybe - Trimming will shorten intake duration. Go back and read the stuff about intake duration. More duration results in reduced low end power and spit back though the carbs.

So MAYBE you can trim the piston - just need to understand what it will do to duration and if you can live with the side effects

BTW - How are you determining TDC with the piston - Top of dome at top of cylinder - or side of piston edge at top of cylinder ?

With edge at top of cylinder, (dome above) my aftermarket piston completely clears the intake

Joined

·

3,595 Posts

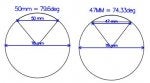

Ok, that makes since measuring across, but if 47mm Wide across aren't we basing the 65% rule on the Radius of the 78mm Bore? If 47mm Wide which should equal about 74.33deg, a 50mm Wide Port would equal about 79.6deg.Port rubs work ok for duration (height of port)

But they don't work for width of port the way you are describing. When you lay the paper flat and measure you get the Arc length- not the Chordal length See below for difference.

Early on - I used a toothpick for measuring width. Keep making it smaller with a nail clipper, until it just fits into the port. Then measure it with a ruler, micrometer, whatever you have.

Now I use an old inside caliper I found at a rummage sale.

Attachments

-

13.3 KB Views: 86

Joined

·

3,595 Posts

Yea, I was thinking about that last night. I was putting the Dome at TDC. I had a piece of Clear Plastic left over from my Glass Bead Cabinet fix, and I layed it on the work bench with Cylinder upside down and just pushed Piston down till hit the Plastic, then looked at it. I was originally thinking if I could CC the Piston Dome area with the Clear Plastic and Piston that way and never made the adjustment. I was in a hurry, my TV Show was coming on. I need to put Piston Edge at TDC and then look at again to see if it clears the Intake Port. I have one of them Inside Calipers also, but I can't find it now. Need to clean the Shop up. If the Dome is 4mm = 0.1574798" High, I would think the Skirt still covers the Intake Port a little if when Piston Dome is at TDC, roughly 1/4" was blocking the Port, but I'll double check it. My New Pistons came today also, so maybe I can compare Pistons also.Do you want to trim the piston ? Yes and Maybe

Yes - if the piston hangs down in the cylinder it is restricting flow so trimming would help that.

Maybe - Trimming will shorten intake duration. Go back and read the stuff about intake duration. More duration results in reduced low end power and spit back though the carbs.

So MAYBE you can trim the piston - just need to understand what it will do to duration and if you can live with the side effects

BTW - How are you determining TDC with the piston - Top of dome at top of cylinder - or side of piston edge at top of cylinder ?

With edge at top of cylinder, (dome above) my aftermarket piston completely clears the intake

Joined

·

1,323 Posts

65% guideline for port width is based on bore diameter - (not radius)Ok, that makes since measuring across, but if 47mm Wide across aren't we basing the 65% rule on the Radius of the 78mm Bore? If 47mm Wide which should equal about 74.33deg, a 50mm Wide Port would equal about 79.6deg.

78mm bore = 100%

78mm bore x 65% = 50.7mm chordal width

47mm wide port calculates as.. 47mm/78mm = 60.3% of Bore diameter.

Joined

·

3,595 Posts

Ok. Got this Piston at TDC now and it doesn't block the Intake Port now. Also Piston at BDC flush with Exhaust Port.65% guideline for port width is based on bore diameter - (not radius)

78mm bore = 100%

78mm bore x 65% = 50.7mm chordal width

47mm wide port calculates as.. 47mm/78mm = 60.3% of Bore diameter.

Attachments

-

25.5 KB Views: 88

-

33.3 KB Views: 45

-

27.6 KB Views: 46

-

26.1 KB Views: 50

Joined

·

3,595 Posts

More photo's.

Attachments

-

33.7 KB Views: 83

-

24.7 KB Views: 47

-

35.4 KB Views: 47

-

28.4 KB Views: 45

Joined

·

3,595 Posts

More.

Attachments

-

23.8 KB Views: 82

-

22.6 KB Views: 40

-

30.4 KB Views: 45

Joined

·

3,595 Posts

On this 335 Intake Port, would you buildup to meet the Sleeve Intake Port Edge or just match the Sleeve to the Aluminium Port?

If the Intake Port is lowered to TNT Spec's that area would be cleaned up also.

Would you match the Aluminium Bridge material at the Top to the Sleeve?

If going bigger than a 34mm Carb, the ID would have to be machined also. You could probably just use a Metal Hole Saw in a Drill Press, your not going that deep.

If the Intake Port is lowered to TNT Spec's that area would be cleaned up also.

Would you match the Aluminium Bridge material at the Top to the Sleeve?

If going bigger than a 34mm Carb, the ID would have to be machined also. You could probably just use a Metal Hole Saw in a Drill Press, your not going that deep.

Attachments

-

33.3 KB Views: 87

Joined

·

3,595 Posts

There are expensive Metal Hole Saws if your going to do a lot of Cylinders and there is cheap Hole Saws that will still do quite a few holes since your cutting only Aluminium. I like Milwaukee Brand myself. This whole set is $79. The single Cutter is around $105. For a 38mm Carb you need a 39mm Hole. 39mm = 1.535428" or 1.5" Hole Saw. There is a Allen Screw to take the drill bit out. Your not going that deep.

Attachments

-

15.7 KB Views: 75

-

39.6 KB Views: 45

41 - 60 of 66 Posts

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 8M

- members

- 175K

- Since

- 2002

A forum community dedicated to Ski-doo snowmobile owners and enthusiasts. Come join the discussion about trails, racing, performance, modifications, classifieds, troubleshooting, maintenance, and more!

Our Vendors

View AllTop Contributors this Month

View All

bossboy

1.1K Replies

ronsmith409

670 Replies

G-Doo13

517 Replies